The Impact of Paint Booth Filters on Auto Painting Outcomes

Auto painting is a complex and delicate process, where success hinges not only on the skill level but also closely on the quality of the painting environment. Paint booth filters play a crucial role in this context. High-quality paint booth filters effectively remove particles, dust, and impurities from the air, ensuring that contaminants do not adhere to the surface of the items being painted. This prevents uneven coating, bubbling, or contamination, ensuring the quality of the coating and enhancing the consistency and stability of the painting results. Moreover, the right filters can significantly reduce the emission of harmful gases into the air, protecting the environment. Therefore, paint booth filters play an indispensable role in auto painting projects, ensuring the safety and health of the working environment while directly affecting the quality of the painted surface and the success of the final outcome.

Types and Functions of Paint Booth Filters: Boosting Painting Operation Efficiency

When choosing paint booth filters, there are many different types to consider, each with its unique functions and advantages. Here are expert picks of 7 common types of paint booth filters that can enhance the efficiency and quality of your painting operations:

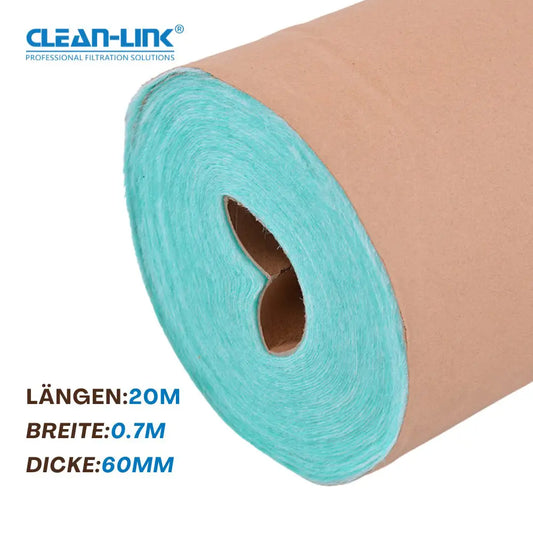

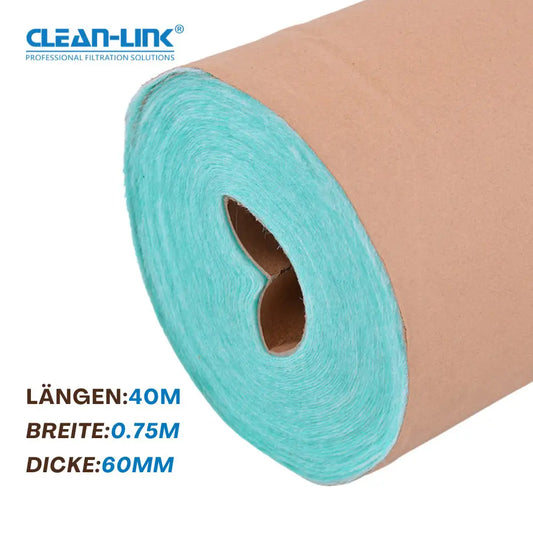

1.Paint Booth Ceiling Filter Media

Ceiling filters, essential in surface coating industries, are finely engineered filters designed for precise spray filtration. Installed atop spray booth ceilings, they ensure consistent airflow distribution while effectively eliminating dust and dirt particles that traverse pre-filters.

2.Fiberglass Paint Stop Filter

Widely adopted across automotive, furniture, and machinery sectors, fiberglass paint arrestor filters feature a progressive open-cell structure, proficiently capturing and eliminating paint mist and solvents generated during coating processes. Notably resilient and corrosion-resistant, they endure diverse solvents, acids, alkalis, and high temperatures.

3.Hot-melt Pocket Filter

Bag filters, strategically positioned in spray booth pre-filter arrays, consist of a series of filter bags housed within a sealed enclosure. Drawing air in via fans, these bags intercept and adsorb dust particles and paint mist, ensuring purified air emission and elevated filtration performance.

4.Paint Pocket Bag Filter

The Paint Pocket Bag Filter is highly adaptable, suitable for both existing exhaust systems in paint booths and for use in repair booths without downstream filters, offering an ideal solution for diverse environments.

Its unique diamond-shaped structure design increases the filter's surface contact area, significantly enhancing the efficiency of capturing paint overspray. Capable of removing overspray particles as small as 10 microns (μm), it achieves a minimum filtration efficiency of 99.8%.

Compared to traditional Fiberglass Paint Stop Filter, the Paint Pocket Bag Filter extends the service life and replacement cycle by three to four times, effectively saving costs for businesses.

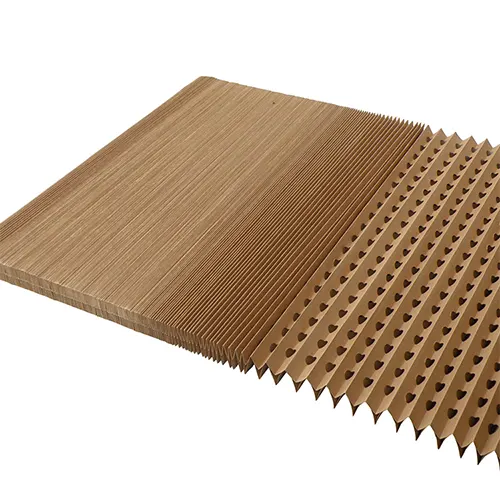

5.Paper Filter For Paint Booth

Paper Filter For Paint Booth also called Accordion filter.These filters are constructed of pleated paper in an accordion shape, which is highly effective for capturing overspray in spray booths. The unique design features a V-shaped front wall that prevents overspray bounce-back and a deeper V-shaped back wall that traps overspray within its pockets, enhancing efficiency in capturing paint particles.

6.Columbus Overspray Filters

Columbus Overspray Filters are advanced multi-layered paint collectors comprised of slit kraft paper and expanded kraft paper, topped with a final layer of micro mesh for optimal performance.

Easily installed, highly efficient, and anti-static in nature, these filters are designed to excel in various work environments, including hand-painting, electrostatic spraying, and high-pressure airless spraying.

7.Box Filter

Box Filters are crafted from fire-retardant corrugated cardboard, offering optimal performance as pre-filters within multi-stage filtration systems. These filters ensure superior dry separation, while their cost-effective and efficient replacement and disposal in incineration plants make them an ideal choice.

In summary, selecting the appropriate paint booth filters is crucial for ensuring the quality and efficiency of painting operations. Choosing the right type and specifications of filters based on actual needs and operational environments can effectively enhance the success rate and quality of painting outcomes.

Maintenance Tips for Paint Booth Filters

To ensure the effective operation of paint booth filters, regular maintenance is essential. Firstly, it's necessary to clean the filters regularly to remove clogged dust and impurities, maintaining effective ventilation. Secondly, replace the filter media timely based on usage, to ensure the continuity and stability of filtration. Additionally, regularly inspecting the paint booth's ventilation system and other related equipment to ensure their proper function is an important step in maintaining paint booth filters.

How to Choose the Right Paint Booth Filter According to Your Needs

Choosing paint booth filters involves considering multiple factors, including the type of filter, performance, cost, and specific operational requirements. Depending on the painting needs, you can select the appropriate filter type, such as pre-filters, medium-efficiency filters, or high-efficiency filters. It's also important to consider the size of the filter and its applicability to meet the air treatment needs of the paint booth. Lastly, consulting with professionals or suppliers is recommended to obtain personalized advice and guidance for selecting filters for specific auto painting projects.