Introduction

Spray painting is a technique that is valued in various industries for its efficiency and excellent finish. However, professionals often face the problem of "orange peel". This blog post examines the causes of orange peel formation in spray painting and discusses comprehensive strategies for prevention, with a particular focus on spray booth cleanliness, including the important role of fiberglass filters.

What are the causes of orange peel in spray painting?

Paint viscosity and composition: Unsuitable viscosity or incorrect thinning of the paint can lead to uneven application.

Incorrect spray gun setting: Using the wrong nozzle size, air pressure or technique contributes to orange peel.

Environmental influences: Temperature, humidity and airflow in the spray booth affect the drying process of the paint.

Surface conditions: Surface preparation, including cleanliness and application of primer, is critical.

Prevention strategies

Optimize paint properties: Proper mixing and thinning of the paint are critical.

Spray gun technique and settings: Correct nozzle size selection, maintaining a consistent spray distance and angle, and applying thin coats are critical.

Control of the environment: Adjust the temperature and humidity and ensure adequate ventilation.

Preparing the substrate: Proper cleaning, sanding and priming of the surface is necessary.

Maintaining a clean spray booth: The role of filters

A clean spray booth is essential for a flawless finish. Several types of filters contribute to this:

Intake filters: remove dust and particles from incoming air.

Exhaust filters: Intercept overspray and keep the air flow in balance.

Ceiling filters: Ensure that clean air flows downwards above the painting area.

Pre-filters and pocket filters: Capture finer particles and extend the service life of the primary filters.

Paint stop filters (floor filters): Typically installed under the paint booth ventilation grille, these filters are essential for capturing overspray and preventing its recirculation. Their unique fiberglass construction effectively traps paint particles while allowing air to pass through, ensuring a dust-free environment.

Conclusion

Avoiding orange peel in spray painting requires a combination of precise engineering, suitable environmental conditions and rigorous maintenance of a clean spray booth. Understanding the various factors that lead to orange peel and implementing these preventative measures, including the effective use of various filters, especially the glass fiber floor filters, are key to achieving a flawless and smooth paint finish.

Verwandte Produkte

-

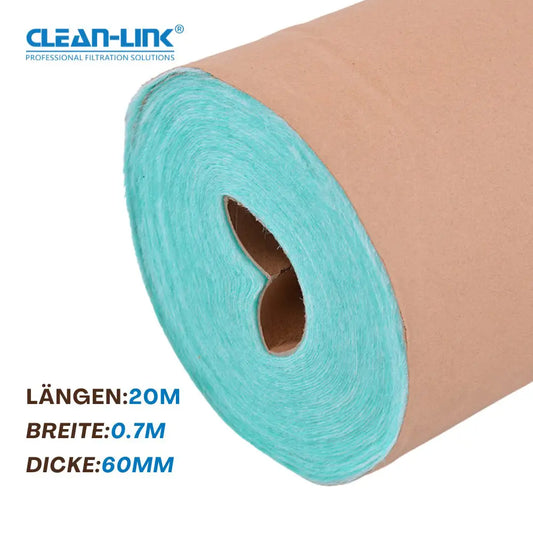

Clean-Link Paint Stop Fiberglass Filters for Spray Booths(0.7m*20m*60mm)

Regular price €40,32 EURRegular priceUnit price per -

Bestseller

Clean-Link Paint Stop Fiberglass Filters for Spray Booths(0.75m*20m*50mm)

Regular price €41,55 EURRegular priceUnit price per -

Clean-Link Paint Stop Fiberglass Filters for Spray Booths(0.75m*20m*60mm)

Regular price €43,20 EURRegular priceUnit price per -

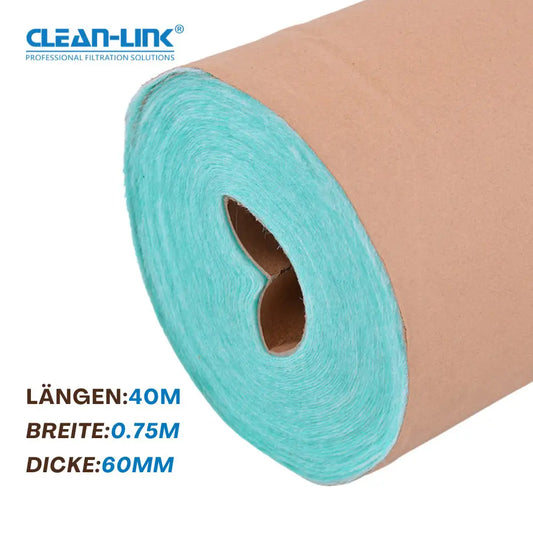

Clean-Link Paint Stop Fiberglass Filters for Spray Booths(0.75m*40m*60mm)

Regular price €86,40 EURRegular priceUnit price per